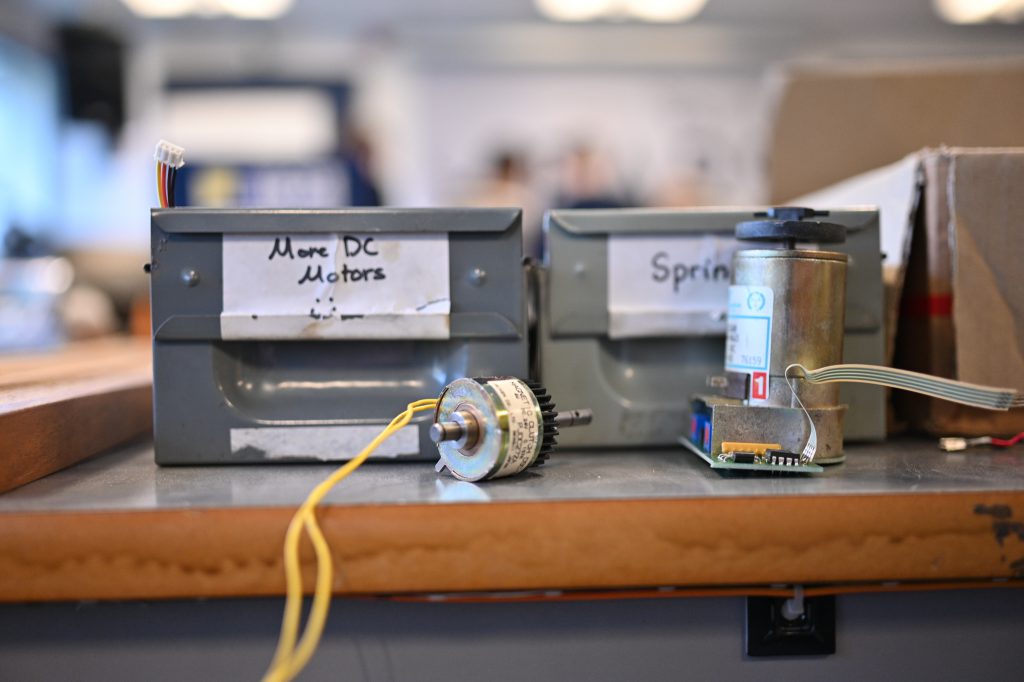

The Electronics and Amateur Radio Society aims to support students in exploring all aspects of electronics, amateur radio, and even space technologies. We do this via our Makerspace, Radio Shack, and all manner of taught courses and social events.

We welcome all students, regardless of their university course! If you have any interest at all in electronics, we’d be delighted to have you.

Contact Us:

Any questions you may have, please feel free to email us at

Committee

The EARS committee ensures the society keeps running smoothly, and organises all the events and courses we offer. We have a committee member for each aspect of the society, so feel free to get in touch if you have queries relating to their area.

Signatories:

President:

Alexandre Symeonidis-Herzig

Vice President:

Caspar Pierce

Treasurer:

David Patyk

Officers:

Project Manager:

Sam Brown

Publicity Officer:

Douglas Potter

Space Officer:

Jakub Filipczyk

Radio Officer:

Caspar Pierce

Electronics Officer:

Alfie Walding